![]()

From Katanas to nanolayered composites, a similar processing route

Rafael Sancho Cadenas: Pre-doctoral UPM-MMEAN (DIMMAT-CM PROJECT)

From 2010, when the Royal Swedish Academy of Sciences decided to award the Nobel Prize in Physics to Andre Geim and Konstantin Novoselov, graphene has become one of the most important topical issues in the world of Materials Science because of its outstanding properties of strength and electrical conductivity.

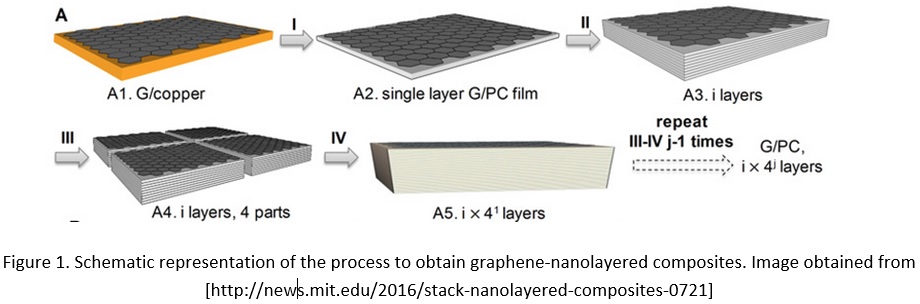

Adapting the folding-forging technique, which was used by Japanese sword-smiths to combine the hardness of high-carbon steel with the toughness of low-carbon steel to create Katanas, researchers from MIT have been able to manufacture composites materials containing layers of graphene. Figure 1 depicts the process that was used by the MIT team, starting with a chemical vapor deposition (CVD) route to make graphene sheets with polycarbonate coating. Then, graphene-polymer layers were stacked, cut and stacked again applying pressure to obtain the bulk composite material.

In the tests, the researchers produced composites with up to 320 layers of graphene and demonstrated the improvement in the strength of the base material. Moreover, the manufacturing technique led to a homogeneous distribution of the graphene, avoiding clustering and short circuiting between layers.

Finally, present achievement places composite materials as one of the most promising disciplines where graphene could be utilized, along with other areas of study such as optical electronics, ultrafiltration and energy storage. Getting high-strength conductive composite materials could replace actual carbon-fiber composite materials due to its electrical conductivity. These new materials would enable to turn away from using heavy copper meshes in aircrafts for lightning strike protection, improving fuel efficiency.

Notwithstanding the high quality of CVD graphene, mechanically exfoliated graphene holds the best physical properties (current conduction, mechanical strength…); but the high price and the limitation of shape and size (small flakes) of that graphene does not make feasible its use.

For more information, check the article: http://news.mit.edu/2016/stack-nanolayered-composites-0721 from MIT news and written by David L. Chandler.