![]()

Multiscale analysis of the radiative properties of materials for high-temperature processes

Author: Dr. Charles-Alexis Asselineau (IMDEA Energy)

The production of high-temperature heat for industrial processes and electricity generation is responsible for more than 54% of global CO2 emissions [1]. In the EU alone, fossil fuels are the source of 40% of the electricity consumed in 2018 [2] and approximately 75% of the energy consumption of energy-intensive industries in 2016 [3]. Without doubts, these two sectors will undergo significant transformations in order to achieve the objectives of the Paris Agreement for the year 2030 notably the replacement of fossil fuels with CO2-free energy sources. The European Union has set the ambitious goal of achieving carbon neutrality by 2050; which imply deep adaptations for the 4 main CO2 emitting industries (electricity production, cement, steel and chemical industry) where fossil fuels will be progressively replaced by alternative fuels (hydrogen, biomass, ammonia, synthetic fuels…), renewable energy technologies capable of producing high temperatures (such as concentrated solar thermal energy) and/or electro-thermal devices powered by renewable electricity, depending on the economy of the processes considered. Beyond current commercial applications, new high-temperature processes operating up to more than 1500 °C and providing economic storage options for electricity [4][5] and alternative fuels [6] are being explored.

The efficiency and economic viability of these technological solutions depend on the proper management of high-temperature heat transfers, notably through the control of the spectral and directional distribution of radiation. At moderate temperatures, the deposition of coating materials makes it possible to promote emission in specific spectral bands. However, at high temperatures (above 650°C), the mechanical stability of coatings is often compromised and metal surfaces are damaged in contact with air. Furthermore, the effectiveness of spectral selectivity decreases as solar and thermal emission spectra overlap significantly.

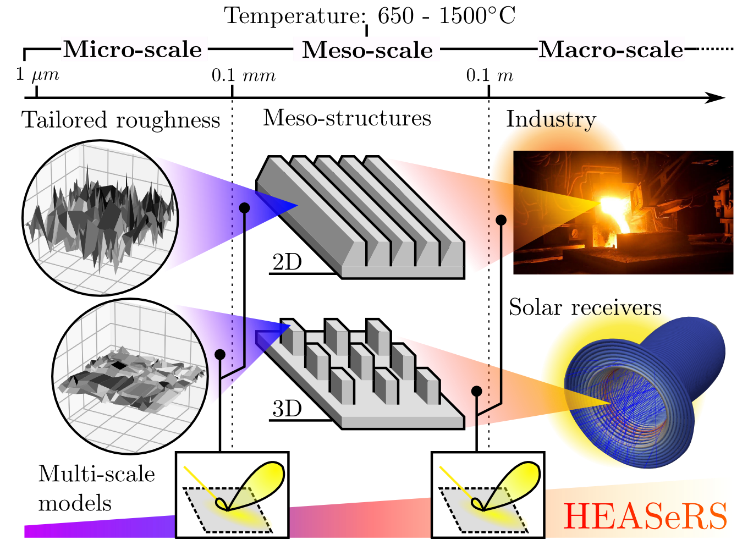

When spectral selectivity becomes unfavourable, it is still possible to make use of angular selectivity via directional control of the radiative properties. This is a less explored route that is used in solar concentration, specifically in cavity receptors to reach higher temperatures than in external receptors, although it is typically not formalized in this way. The geometry of the surfaces that participate in the energy exchanges influence the angular and spectral distribution of the emitted and reflected radiation, independently of the intrinsic optical properties of the material of which they are composed. The MSCA IF HEASeRS (High tEmperature Angular-Selective Radiant Surfaces) project focuses on analysing this influence on the characteristic spectral range of solar radiation and thermal radiation, on materials used industrially in high-temperature applications. This analysis is performed at multiple scales (Figure 1):

- Micro-scale (1 – 100 µm), the influence of surface roughness is evaluated.

- Meso- scale (100 µm – 10 cm), longitudinal grooves and arrays of protrusions and extrusions are considered.

- Macro-scale (>10 cm), the directional radiative properties arising from the combined influence of the micro-scale and meso-scale is analysed. The resulting anisotropic behaviour is applied to the optimisation of radiant devices or higher efficiency and/or lower cost.

Figure 1: Summary of the scientific program of the HEASeRS project

The results obtained have applications in all types of high temperature processes and avoid many of the limitations found in existing concepts.

Focus on industrial applications

To ensure that the work developed in HEASeRS can lead to industrial applications in the short-medium term, materials have been selected in consultation with suppliers, manufacturers and/or users of high-temperature devices. Advanced ceramic materials have also been chosen.

The numerical simulation work in this project is developed using open-source tools in order to be able to distribute it freely and promote a rapid dissemination of knowledge. HEASeRS collaborates with European expert centres to synthesize, modify and measure optical properties of high temperature refractory, ceramic and metallic materials.

References

[1] “Hydrogen From Renewable Power: technology outlook for the energy transition” – IRENA; 09/2018.

[2] “Shedding light on energy in the EU“ – Eurostat; 2020.

[3] “Energy data – 2020 Edition” – Eurostat; 2020.

[4] A. Datas et al., Energy, 2016, 107, 542–549.

[5] C. Amy et al., Energy Environ. Sci., 2019, 12, 334–343.

[6] S. Brynolf et al., Renew. Sustain. Energy Rev., 2018, 81, 1887–1905.

Contact

Dr. Charles-Alexis Asselineau, MSCA IF fellow at IMDEA Energy (High-Temperature Processes Unit) – charlesalexis.asselineau@imdea.org